Some Ideas on Uv Filtration You Need To Know

Table of ContentsMore About Uv FiltrationThe Best Strategy To Use For Uv FiltrationGet This Report on Uv FiltrationTop Guidelines Of Uv Filtration

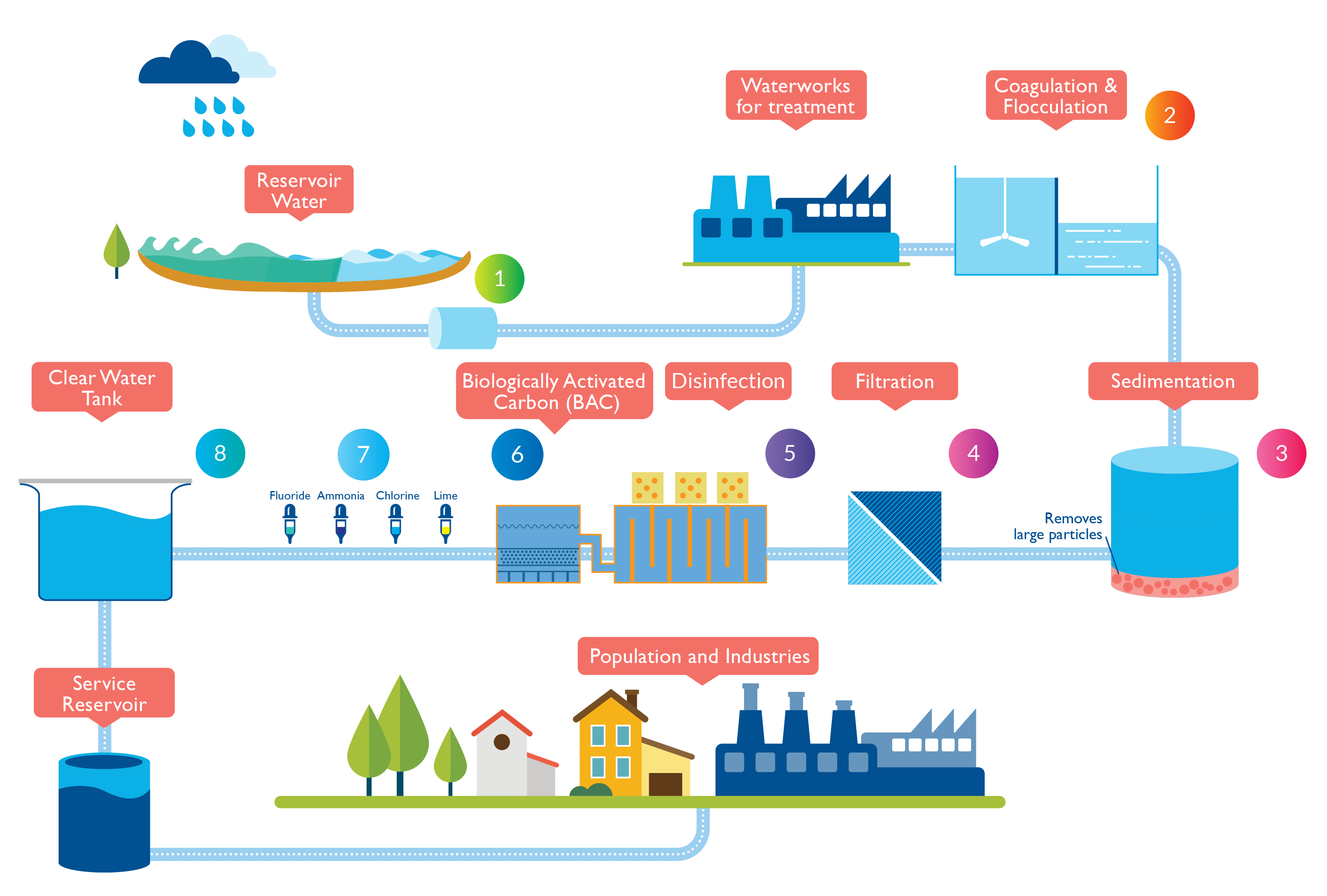

Removal of preference as well as smell compounds from the water.: Softens the water.: Filtering to eliminate small fragments and also disinfection to eliminate viruses as well as bacteria, and also make sure an unsuitable environment for virus and also germs growth throughout the distribution system.

8 Phases of the Wastewater Process Phase One Bar Screening Elimination of large products from the influent to avoid damages to the center's pumps, valves and also various other equipment. The procedure of dealing with and redeeming water from wastewater (any kind of water that has been utilized in residences, such as flushing toilets, cleaning recipes, or bathing, and some water from commercial usage and storm drains) begins with the expectation that after it is treated it will be tidy sufficient to reenter the atmosphere.

Facts About Uv Filtration Uncovered

According to the EPA, The Tidy Water Act (CWA) develops the standard framework for regulating discharges of toxins right into the waters of the United States as well as controling high quality requirements for surface waters. Under the CWA, EPA sets wastewater standards for industry. The EPA has likewise developed national water top quality standards referrals for toxins in surface area waters.

Related White Papers Select Products Stage 2 Testing Removal of grit by flowing the influent over/through a grit chamber. Fine grit that locates its method right into the influent requirements to be removed to avoid the damage of pumps and equipment downstream (or influence water flow). Too tiny to be evaluated out, this grit requires to be eliminated from the grit chamber.

Stage 4 Oygenation Air is pumped into the oygenation tank/basin to motivate conversion of NH3 to NO3 and supply oxygen for germs to proceed to proliferate as well as expand. When news transformed to NO3, the microorganisms remove/strip oxygen molecules from the nitrate particles and the nitrogen (N) is released as N2 (nitrogen gas) - uv filtration.

This begins in the aeration container. The main feature of the oygenation container is to pump oxygen into the container to motivate the malfunction of any natural material (and also the development of the bacteria), in addition to make sure there is sufficient time for the organic product to be broken down.

Getting The Uv Filtration To Work

This process is handled to provide the very best conditions for microbial development. Oxygen gas [O2] levels below 2 ppm will certainly exterminate the bacteria, lowering effectiveness of the plant. Liquified Extra resources oxygen tracking at this phase of the plant is important. Ammonia and also nitrate measurements are common to gauge just how efficient the germs are in converting NH3 to N2.

Phase 5 Second Clarifier Dealt with wastewater is pumped right into a second clarifier to enable any type of staying natural sediment to settle out of cured water circulation. As the influent leaves the oygenation procedure, it flows right into a secondary clarifier where, like the primary clarifier, any very small solids (or penalties) sink to the base of the container.

With the improved concentration of germs as component of the oygenation phase, there is a requirement to check the outbound effluent for germs visibility or lack and to disinfect the water. This guarantees that greater than specified concentrations of bacteria are not launched into the environment. Chlorination is the most usual and also economical kind of sanitation however ozone and UV sanitation are additionally increasing in popularity.

Uv Filtration for Beginners

Water is guided from the Head Tank to the Claricone clarifier. Water gets in the clarifier at the mixing area situated in the base of the Claricone - uv filtration. Lime is included in the water in this area where it reacts with the calcium as well as the magnesium in the water to develop speeds up.

After adequate time, particles adhere to each various other as well check my reference as turn into larger particles, or, floc, which is susceptible to work out in water. This procedure of floc development is called flocculation. To aid in the flocculation of fragments, an anionic polymer is added in the mixing area of the cone. Clarification of water is achieved by the seperation of suspended solids from water by gravity.

The cleared up water actions upward slowly, eventually passing over the effluent dam to the cone electrical outlet as well as on the to filters for more treatment. The water plant integrates a solitary stage lime softening operation to get rid of hardness. Hardness is triggered by the visibility of dissolved bivalent and polyvalent metal ions, mostly calcium and magnesium.

This is included both in the clearwell and also the high service discharge as water enters the distribution system. 2 mg/l is normally preferable in the plant faucet.